Fuel Quality Testing Laboratory

Already know what you need ?

Fuel Quality Testing Laboratory

If you distribute or use fuel, MEG Corp’s Fuel Testing Laboratory can assess fuel quality and troubleshoot fuel-related problems. Changes in fuel have changed how fuel suppliers and diesel users store, handle and use diesel fuel at every point in the distribution chain. It has never been more important to monitor your stored fuel, and depending on your application, have it tested on a consistent basis. MEG Corp not only conducts fuel testing to provide rapid, accurate results, but we interpret the results and provide the appropriate recommendations necessary to address fuel quality concerns. Our testing capabilities utilize ASTM methods and include diesel, biodiesel blends, gasoline and ethanol blends. We provide test results within 24-48 business hours of receiving the sample in our lab.

Common Reasons to Test Fuel:

Look for Contaminants

The most common contaminants found in diesel fuel storage and vehicle tanks is water, bacteria and fungus. It is recommended to test tanks once a year for entrained water and microbial contamination.

Cold Flow Testing

Take the guesswork out of your fuel’s cold weather performance by testing the cold weather characteristics.

Solve Fuel-Related Problems

We utilize fuel testing and visual inspection of fuel filters to troubleshoot, diagnose and provide recommendations for prevention.

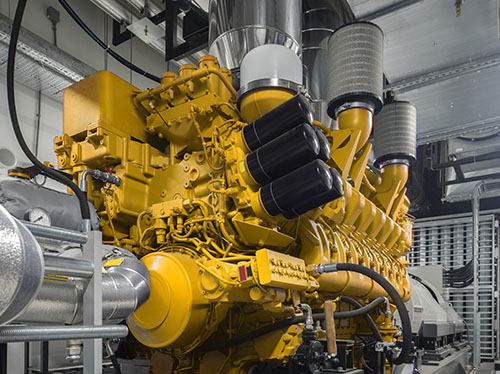

Stand-by Generators

The intent of a backup generator is to provide power when called upon. Just as you routinely test the generator, it is important to test the quality of the fuel to ensure the generator will be able to operate when needed. Many generator OEMs require that the fuel meet strict specifications and because fuel for stand-by generators is often stored for long periods of time, degradation can cause it to fall out of specification. Routine testing assures the fuel is in specification, is free of contaminants and will perform when called upon.

-

Oil Gauging Tape Measure with Grounding Wire – 25 Fee

$175.00 Add to Order -

Basic Generator Fuel Test

$190.00 Add to Order -

Complete Generator Fuel Test

$390.00 Add to Order -

Farm/Fleet Tank Testing

$98.00 Add to Order -

Cold Flow Testing

$87.00 Add to Order -

Plated Brass Bacon Bomb Sampler – 4 oz Capacity

$350.00 Add to Order -

Bacon Bomb Sampler with 25-Foot Oil Gauging Tape Measure Combo Kit

$525.00 Add to Order